The scientists of the Fraunhofer IWS “Advanced Battery Technology Center“ (ABTC) support you in all questions of the value chain for dry battery electrode production.

Our Offer

Feasibility Studies and Process Development

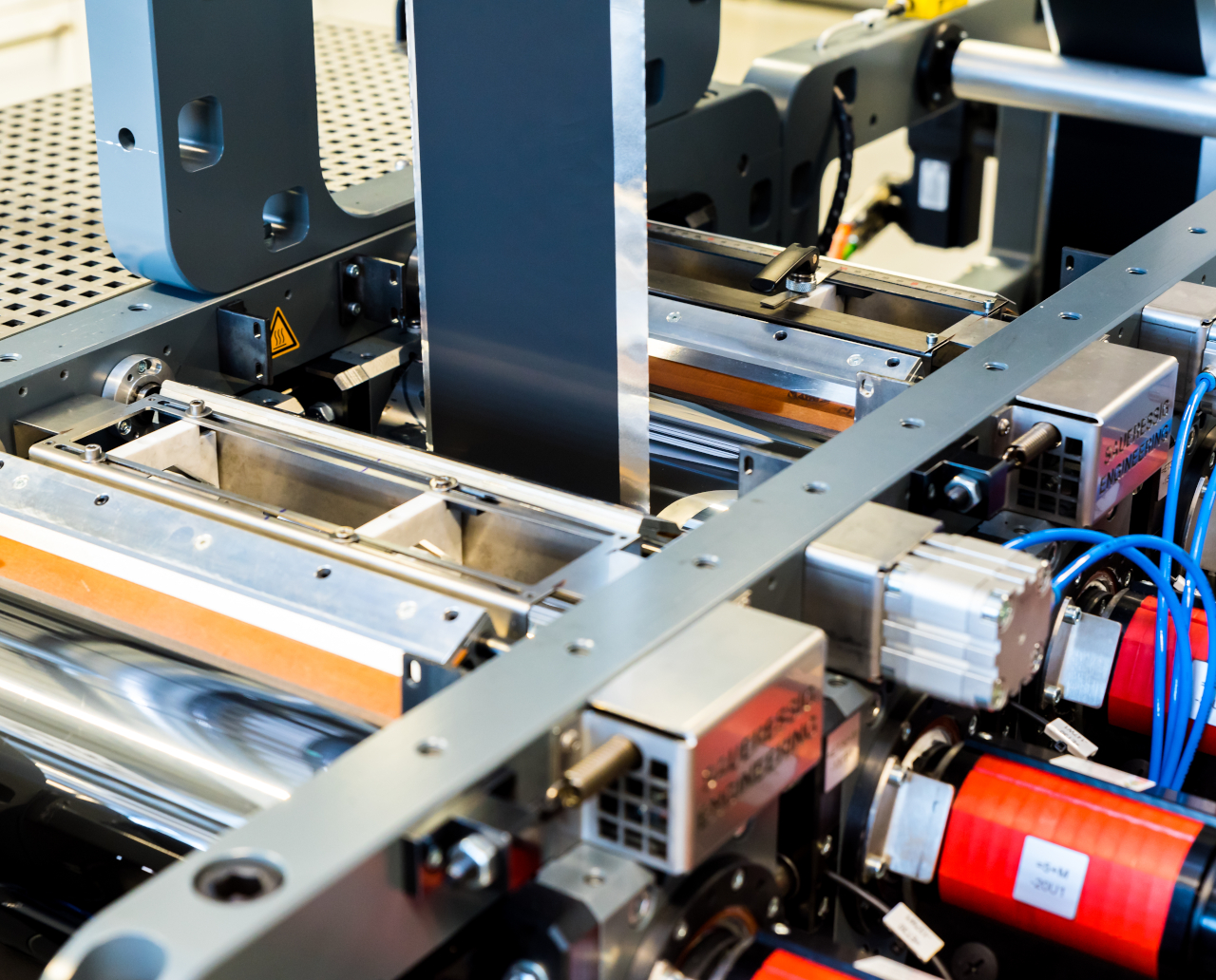

Our research and development services for feasibility studies are directed equally at material manufacturers and cell makers. In addition to evaluating novel active materials, binders, carbon blacks or other components for their suitability for dry coating, we offer parameter studies and process developments from the electrode sheet up to the roll-to-roll scale.

Electrode Characterization

Scanning electron microscopy on several layers of a DRYtraec® NMC electrode.

The material science expertise of Fraunhofer IWS allows an in-depth investigation of the microstructure of DRYtraec® electrodes. In the scanning electron microscope the structure can be examined in several depth layers. By means of EDX additional element specific statements can be made. In button cells or single-layer pouch cells, the electrochemical behavior of the electrodes can be analyzed. Further methods of spectroscopy, X-ray diffraction and porosimetry allow a comprehensive evaluation of the DRYtraec® electrodes.

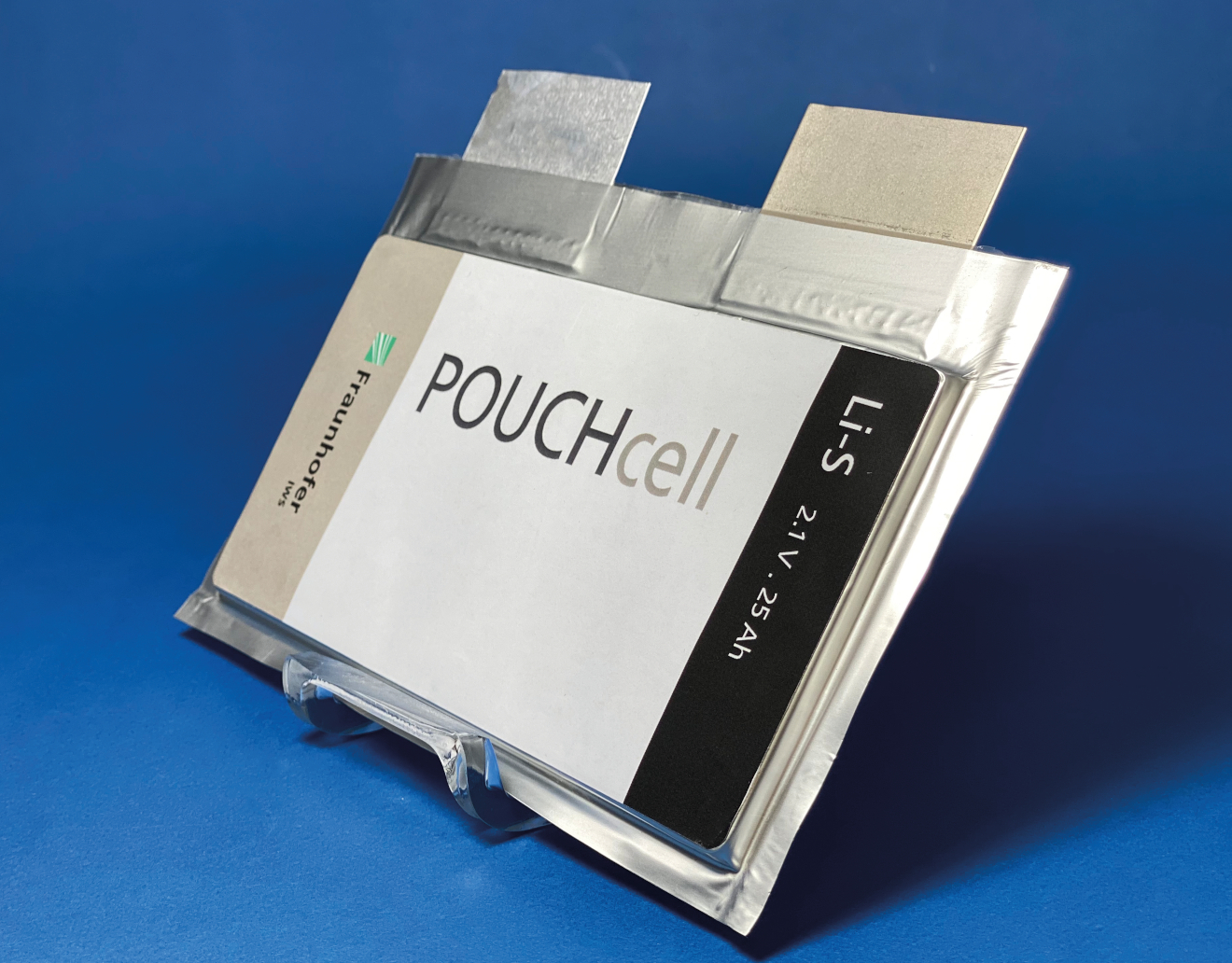

Cell Structure and Evaluation

A process line for the fabrication of pouch cells at Fraunhofer IWS enables the evaluation of performance characteristics of battery electrodes under conditions close to the application. Thereby, many years of experience in the manufacturing of lithium-ion, lithium-sulfur and solid-state battery cells can be drawn upon. The evaluation is performed under variable, defined conditions (external pressure, temperature, performance profiles).

Technology Transfer and Licensing

Fraunhofer IWS offers system solutions up to prototype scale for R&D systems. The focus is on customized special designs. For larger scale plants we support the specification and realization in cooperation with plant manufacturers. The technology transfer to our partners includes training and consulting programs up to the support of acceptance and commissioning processes. The commercial use of our technology is made possible within the framework of licensing agreements.