DRYtraec®: Dry Battery Electrode Coating Technology Enables Environmentally Friendly Battery Cell Production

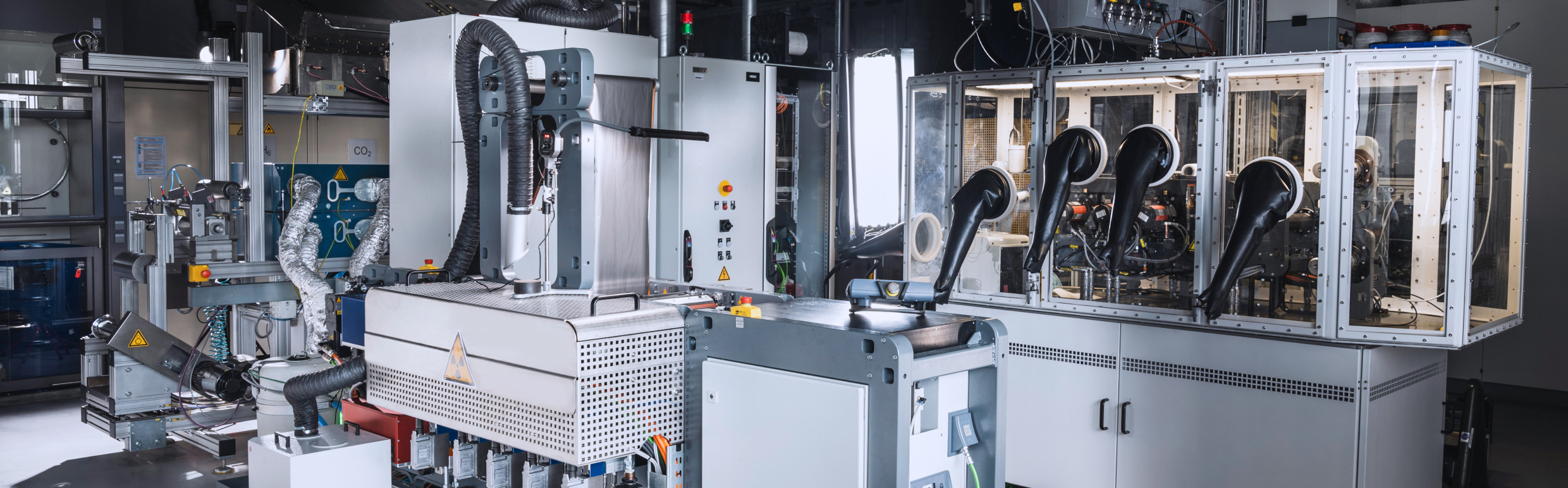

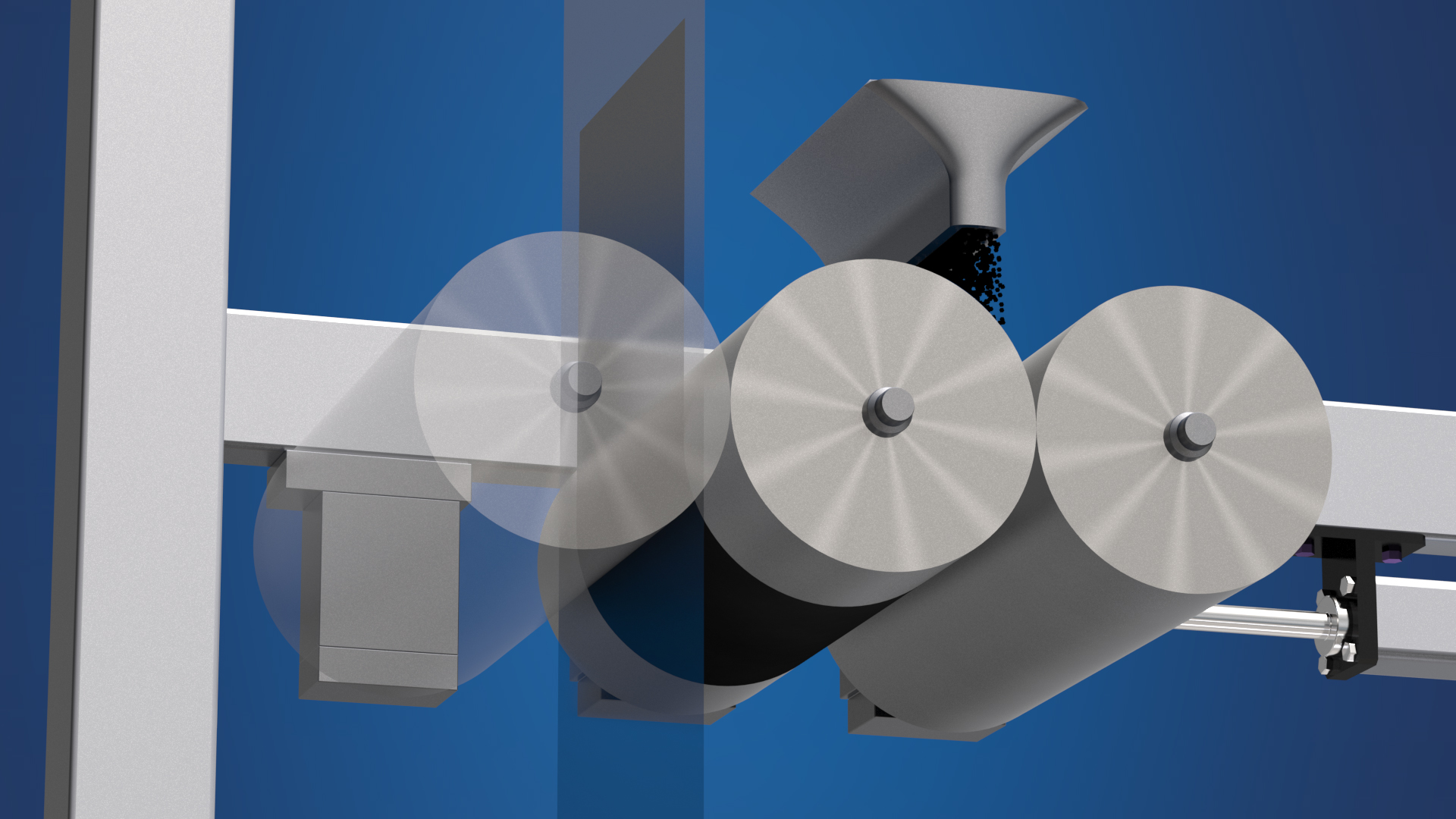

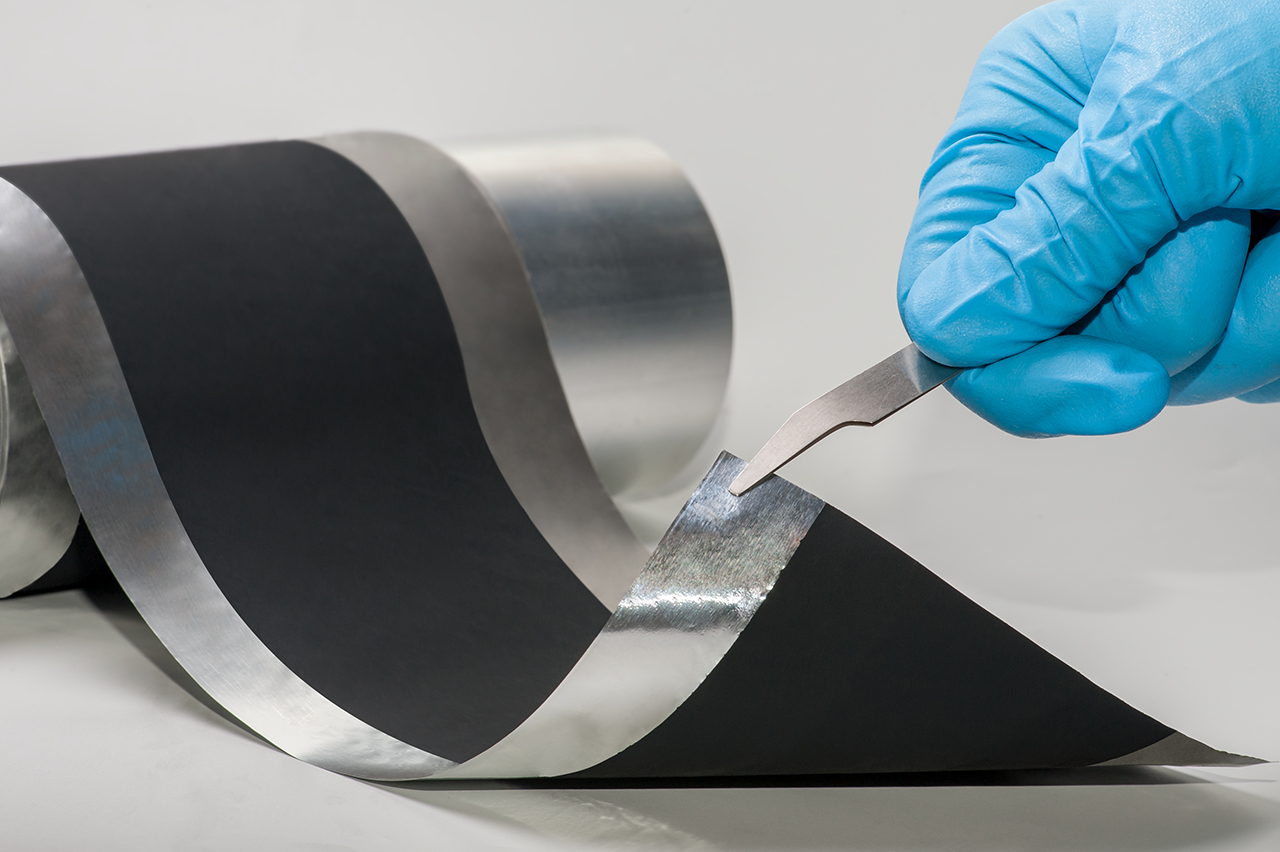

The DRYtraec® (Dry transfer electrode coating) process developed at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden allows the completely solvent-free and thus environmentally friendly and cost-saving production of battery electrodes.

In order to produce batteries more cost-efficient and more environmentally friendly in the future, Fraunhofer IWS scientists have developed a new production process. Instead of using liquid chemicals, they coat the electrodes for battery cells with a dry film. This saves energy costs and eliminates the need for toxic solvents in this process step.

Improved and more cost-efficient production methods for energy storage systems are increasingly requested in Germany: All major automotive manufacturers have launched ambitious electric vehicle programs that will lead to a growing demand for battery supply in the near future. So far, German companies have been purchasing the cells from Asian companies, which have decades of experience in the mass production of battery cells. A lot of energy is consumed in these processes. This makes battery cell production cost-intensive in locations with high electricity prices such as Germany. The patented DRYtraec® technology of Fraunhofer IWS can make a decisive contribution to a more environmentally friendly and cost-efficient cell production in the future.

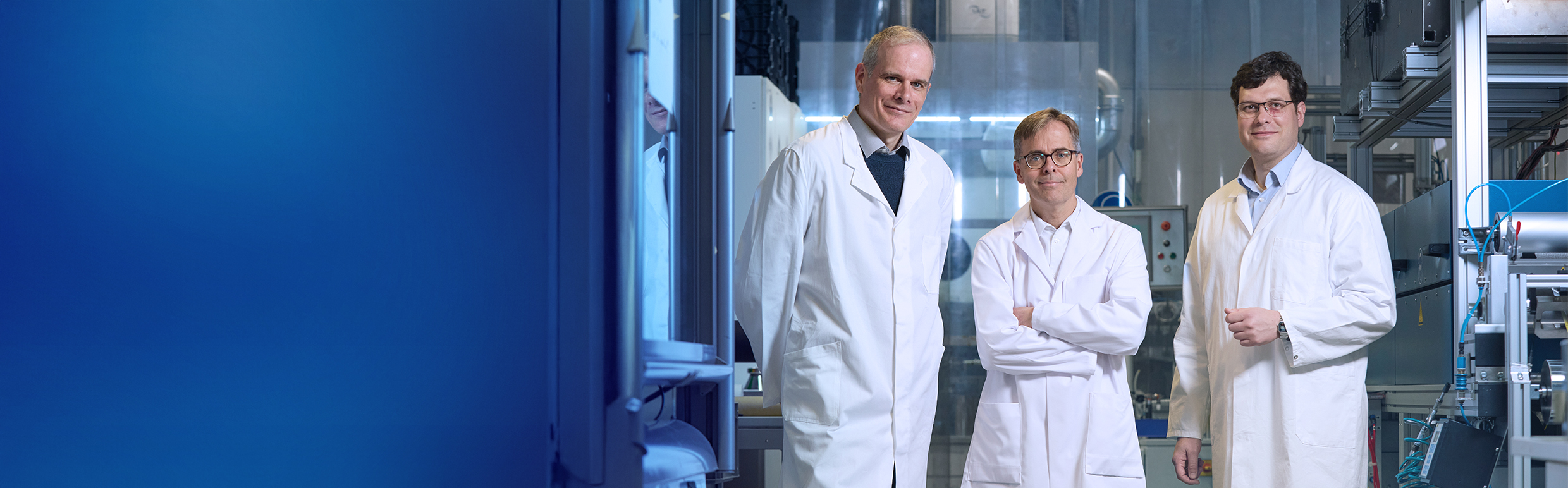

The broad competence profile of the battery researchers at Fraunhofer IWS allows a holistic view on development topics from the material to the prototype cell. At the “Advanced Battery Technology Center“ (ABTC), aspects of dry coating are advanced both on a laboratory scale for novel battery technologies and on an industrial prototype scale for process and equipment development.